rockwell hardness test to tensile strength|hardness to tensile strength calculator : service Hardness testing to Brinell is mainly performed with HBW 1/30 or HBW 2.5/187.5. For hardness testing to Rockwell, scale B (HRB) is used for fasteners of property class 4.6 - 6.8 and scale C (HRC) for property classes . webSheffield Wednesday x Southampton – Sexta-feira, dia 4 de agosto de 2023, às 16:00, horário de Brasília. Na sexta-feira teremos o início da disputa da segunda divisão do campeonato inglês, e começa a corrida por uma vaga na Premier League da temporada 24/25. A segunda divisão inglesa leva os 2 primeiros colocados diretamente para a .

{plog:ftitle_list}

Resultado da 25 de set. de 2023 · Requisitos y formación para trabajar. Para trabajar como croupier, es importante cumplir con ciertos requisitos y recibir una formación especializada. A continuación, te enumero los principales: Edad y apariencia: En la mayoría de los casos, debes tener al menos 18 años y cumplir .

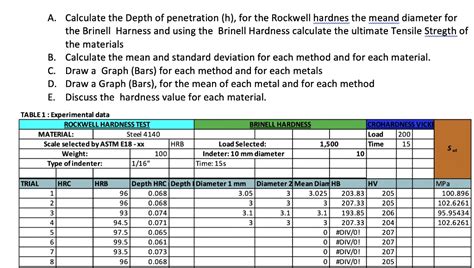

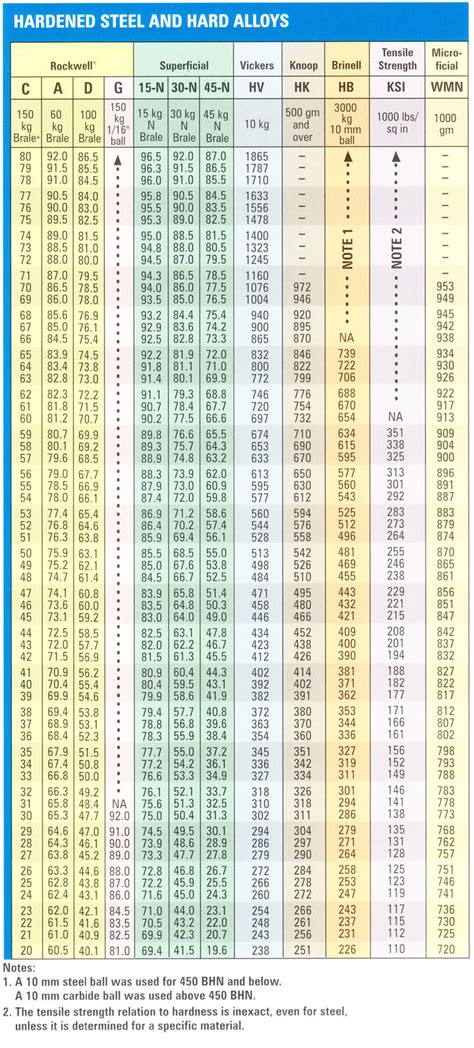

The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate.Conversion of hardness-to-hardness or hardness-to-tensile-strength values for unalloyed and low alloy steels and cast steel per. ISO 18265 - 2013. Hardness conversions are no substitute .Hardness testing to Brinell is mainly performed with HBW 1/30 or HBW 2.5/187.5. For hardness testing to Rockwell, scale B (HRB) is used for fasteners of property class 4.6 - 6.8 and scale C (HRC) for property classes .Class #2 (1) Enter Rockwell B scale hardness and tensile strength data appearing in Table 6 (Reference [5]) or alternatively in Wilson (Instron) Desk Chart 60 [7], for soft steel, gray and malleable cast iron and most non-ferrous metals, into Excel (or equivalent) and plot tensile strength as a function of Rockwell hardness and

Then several other hardness tests have been developed, including the Vickers, Berkovich, Knoop and Rockwell tests [2], [3], [4]. . this could be attributed to the different fracture strength under hardness and tensile test, by the way, the lower shear-ability and the cleavage cracking becomes much easy also could induce the increase in the .The definition of hardness differs from the definition of strength, which is the resistance of a material to deformation and separation. . Vickers and Rockwell. Hardness testing in the low-load range applies when the test load falls between an interval of 0.2 kgf . Tensile Test ISO 527-1/-2; Tensile Test ISO 6892-1; Flexure Test ISO 178 . ASTM E10: This standard covers Brinell hardness testing in metallic samples. ASTM E18: This standard includes the various ways that Rockwell hardness can be measured by standard methods, specifically for metallic materials. ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness .a universal tester is used to test the tensile strength and compressive strength of materials. An earlier name for a tensile testing machine is a tensometer. . Rockwell hardness test (scales A, B & C) methods : IS:1586-1988 Viva Questions: 1. What is Hardness? 2. What is the significance of minor load in Rockwell method of hardness testing

Converted from Brinell Hardness Value: Hardness, Rockwell B: 60: 60 Converted from Brinell Hardness Value: Hardness, Vickers: 107: 107 Converted from Brinell Hardness Value: Ultimate Tensile Strength: 310 MPa: 45000 psi AA; Typical: Tensile Yield Strength: 276 MPa: 40000 psi AA; Typical: Elongation at Break: 12 %: 12 % AA; Typical; 1/16 in. (1. .Tensile strength can be calculated from hardness and is easy to determine because hardness tests — such as Rockwell — are simple to perform, inexpensive, and non-destructive because only a small penetration is performed on the specimen. For many metals, tensile strength increases as hardness increases. Young’s Modulus

rockwell to tensile strength calculator

AISI 304 Stainless Steel (UNS S30400, SS 304) AISI 304 stainless steel (UNS S30400) is the most widely used stainless steel, containing 18-20% Cr and 8-10.5% Ni, and also known as 18-8 stainless steel.SS 304 is non-magnetic under annealing conditions, but after cold working (such as stamping, stretching, bending, rolling), part of the austenite structure may be converted into .Ultimate tensile strength of Ti-6Al-4V – Grade 5 titanium alloy is about 1170 MPa. The ultimate tensile strength is the maximum on the engineering stress-strain curve. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester .RockwellKnoop Brinell Tensile Strength Micro-B F G A E H K 15-T 30-T 45-T HK HB HB HV KSI WMN 100 kg 1/16” ball 60 kg 1/16” ball 150 kg 1/16” ball 60 kg Brale 100 kg 1/8” ball 60 kg 1/8” ball 150 kg 1/8” ball 15 kg 1/16” ball 30 kg 1/16” ball 45 kg 1/16” ball 500 gm and over 500 k g 10 mm ball 3000 kg 10 kg 1000 lbs/ sq in .The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C scale is also the most precise way to report metal strength used in industrial machine knives. . if you’ve ordered tough blades with tensile hardness in the RC 60 scale, you can rest assured we .

hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . properties of materials, such as tensile strength and machinability. Furthermore, indentation hardness has become one of the most reliable controls of the heat treatment and .Hardness tests (continued) • Rockwell and superficial rockwell . • Hardness conversion . Chapter 6 - Correlation between hardness and tensile strength • Relations between hardness and tensile strength for steel, brass, and cast iron.

The hardness value is near the limit (within 15%) of the acceptable range of the particular hardness scale. * The many hardness tests listed here measure hardness under different experimental conditions (e.g. indenters made in different sizes, shapes, and materials, and applied with different loads) and reduce their data using different formulae.SS410 has good tensile strength, creep and fatigue strength and other mechanical properties, mainly used in steam turbines, jet engines and gas turbines. . yield strength, elongation, reduction in area, Brinell and Rockwell .Type 316L stainless steel density is 0.289 lb/in3 (8.0 g/cm3); melting point is 1375-1400 °C (2500-2550 °F); 0.2% yield strength is minimum 25 ksi (170 MPa) in annealed and hot finished condition, minimum 45 ksi (310 MPa) in annealed and cold finished condition; Minimum tensile strength is 70 ksi (485 MPa) in annealed and hot finished .

To convert Rockwell Hardness to Tensile Strength, use a polynomial equation developed by modeling the tested materials. The general formula is: TS = c3 * RH^3 + c2 * RH^2 + c1 * RH + c0. . The Brinell hardness testing uses a 10mm hardened steel ball, while the Rockwell test uses either a much smaller steel ball (<4mm) or a diamond cone .The Brinell hardness number can be correlated with the ultimate tensile strength (UTS), although the relationship is dependent on the material, and therefore determined empirically. . Leeb rebound hardness test; Rockwell scale; Vickers .This results in 30 different Rockwell scales standardized according to ISO 6508 and ASTM E18 (e.g., A, B, C, 30N, 15T) or Rockwell test methods (e.g.: HRA, HRBW, HRC, HR30N, HR15TW), each covering different hardness ranges and consequently the widest variety of materials and applications (see table below).

Hardness test methods and hardness conversion tables Introduction. . The table shows a set of values that has been used for stainless steels and also includes a tensile strength, (UTS), comparison. The Rockwell B values are superimposed on this table using an approximation from ASTM E140 Table5, which compares Rockwell B and Brinell .By way of correlation with other material properties, the Rockwell hardness test can provide important information about metallic materials, such as the tensile strength, wear resistance, and ductility. The test is generally useful for material selection, for process and quality control, and for acceptance testing of commercial products. .

rockwell hardness scale comparison chart

Ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 290 MPa. . Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration .

for tensile strength in units of MPa (Ref 30).To generate a curve for Eq 6, diamond pyramid hardness values between 100 and 650 were converted to Brinell hardness according to ASTM E140-05 (Ref 29) and the tensile strength was calculated.Figure 4(a) shows Eq 6 overlaid on the tensile strength-hardness data. Figure 4(b) illustrates the difference in the predicted .

Ultimate Tensile Strength. Ultimate tensile strength of duplex stainless steels – SAF 2205 is 620 MPa. The ultimate tensile strength is the maximum on the engineering stress-strain curve. This corresponds to the maximum stress that can be sustained by a structure in tension. Ultimate tensile strength is often shortened to “tensile strength .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the . The ultimate tensile strength is the maximum on the engineering stress-strain . Common indentation hardness scales are Brinell, Rockwell and Vickers. Rebound hardness. Rebound .Ultimate tensile strength of Inconel 718 depends on heat treatment process, but it is about 1200 MPa. . Brinell hardness test is one of indentation hardness tests, that has been developed for hardness . Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where .

rockwell hardness scale chart

rockwell hardness conversion chart

WEBASABA BRANCH. Country: Nigeria. Address: 287 Nnebuisi Road Asaba, Delta State. View Detail. Opening Hours: Closed ASABA BRANCH 2. Country: Nigeria . SLOT Systems .

rockwell hardness test to tensile strength|hardness to tensile strength calculator